From the first minute it is 'efficiency first' at Greenpack. We use a fixed protocol for every load of product that arrives. This starts with accurate registration of the products: does the number of packages match the description of you as the client? The pallets are then entered into the inventory system, ready for further processing.

Our inspectors check the quality of the product based on a visual inspection. Externally, but also internally: brix content and temperature are accurately recorded. Greenpack has a RIK-certified quality system, which allows us to carry out an efficient self-inspection. Each pallet receives its own ID code, linked to the inspection report. The history of the pallet can be viewed at any later time based on the ID code.

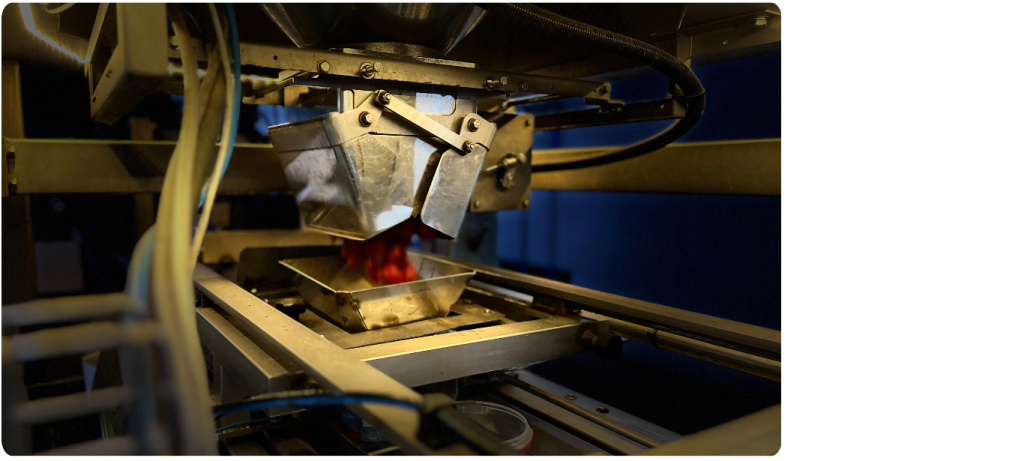

The complete processing process within Greenpack is focused on customer-specific packaging. Within Greenpack we are able to respond well to the various wishes of retailers and other clients. Experienced, well-trained employees are familiar with processing all common small packages. Do you have special requirements regarding the weight or color of the product? Do products have to meet a certain ripening class? Would you like to communicate additional information via a sticker?

We will meet all your questions in consultation. The large number of packaging lines that are operational on a daily basis guarantees rapid switching. Greenpack uses the most advanced packaging techniques. Processes have been extensively optimized from both the point of view of hygiene and speed.

Your customer counts on a product according to the agreed specifications. That is why an outgoing inspection is a standard part of the permanent Greenpack protocol. No detail escapes our control: weight, packaging, product type and other characteristics are accurately recorded.

The information can be found in the inspection report that is maintained for each pallet number. Reports are always available for later party tracking and tracing. You can also make agreements with Greenpack about taking tests. In our packaging and distribution center we have the right conditions to carry out tests according to fixed protocols.

Versproducten leveren staat of valt met een gestroomlijnde logistiek en distributie. Producten die verpakt of omgepakt zijn, worden direct gepalletiseerd voor verzending. Met een vertrouwd team aan orderpickers blijft ook in het logistieke traject de snelheid hoog. Ervaren en goed getrainde medewerkers dragen zorg voor een optimale bescherming van kwetsbare producten. Ook weer op basis van klantspecifieke vragen kan elke pallet worden voorzien van hoeklatten en banden voor versteviging. Daarna staan alle seinen op groen voor de verdere distributie. En ook dan is Greenpack u graag van dienst: met het aanleveren van alle benodigde CMR-formulieren. Het enige wat uw chauffeur nog hoeft te doen, is tekenen voor ontvangst. Kan het efficiënter?

Do you not need products immediately? There are more than enough facilities in our packaging and distribution center. Optionally, you can also use conditioned facilities if products require this. Greenpack also offers you the opportunity to skip your products.

Flowpack is the most commonly used packaging variant. Greenpack has gained extensive experience with every type of flow pack packaging. This way you are assured of an efficient, error-free packaging process.

Vegetables such as cucumber can be sold hygienically in sealed packaging. A seal also offers more protection in the store.

The Topseal is an ideal packaging for a more luxurious presentation of the product.

The perforations in the sealing film ensure optimal air supply, which is better for the fruit and vegetable product. This ensures that the product arrives in the store in top condition.

With the shaker cup you can offer consumers more convenience. This makes it the ideal packaging for snack vegetables such as tomatoes and cucumbers.

Do your products require a little more strength during transport or presentation in the store? Packaging in a bowl or clamshell is the solution.

Do you have other wishes regarding your own packaging? Then it is good to know that Greenpack works in a customer-friendly manner. We are happy to discuss the possibilities for your company and actively think about the most efficient application!